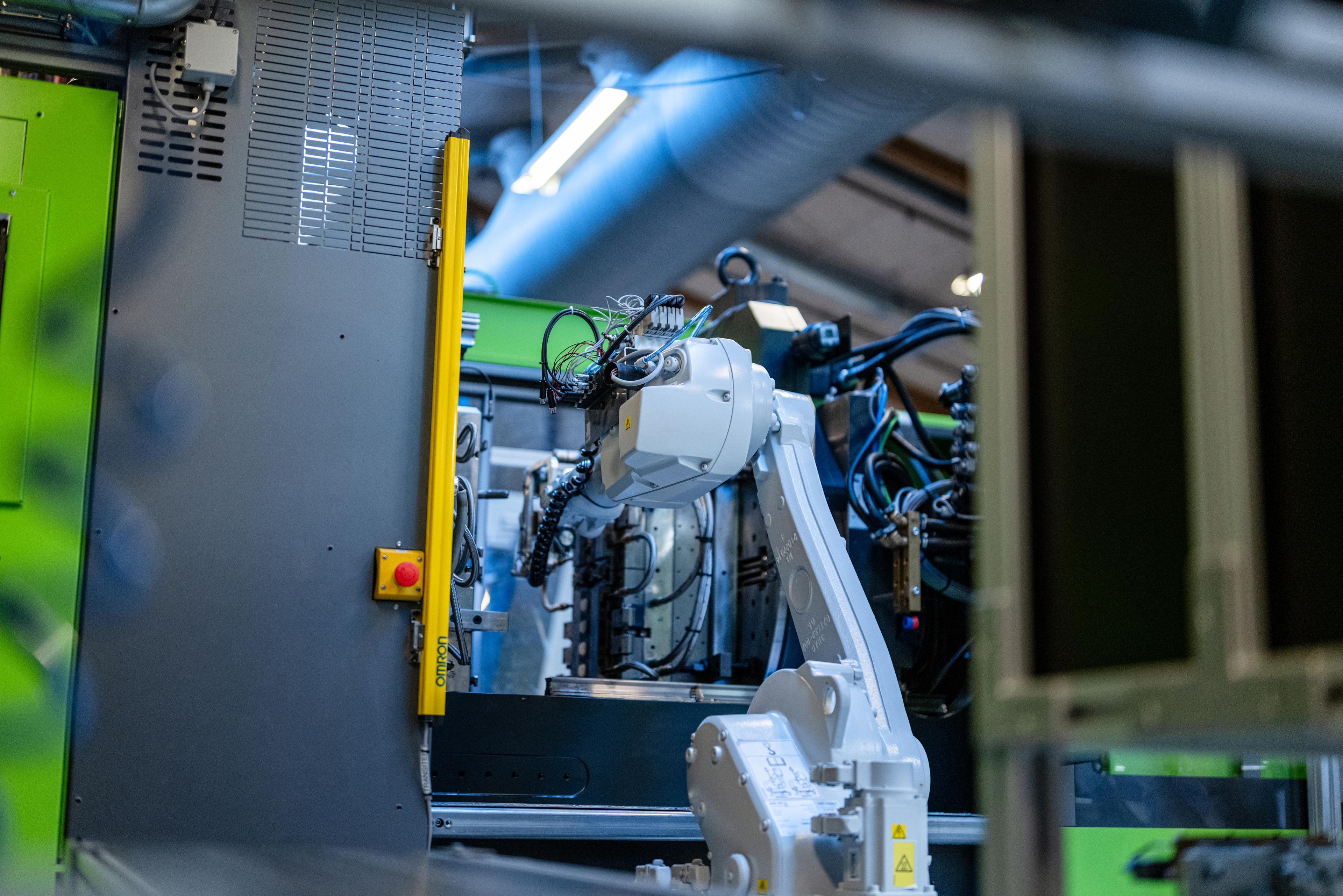

Injection Moulding

Precision components from 480+ machines worldwide

What this solution offers

With more than 480 injection moulding machines, including 50 two- and three-component IM Machines, SP Group is among Northern Europe’s largest independent moulders. Servo-electric IM Machines up to 1,500 t make technical parts for Healthcare, Cleantech and Foodtech.

Cleanroom Class 7 & 8 cells produce medical disposables under ISO 13485, while vertical rotary tables handle insert-moulded electronics. Automation cells integrate vision inspection, laser engraving and packaging, pushing OEE above 85 % and meeting FDA/GAMP validation.

We source, test and qualify steel moulds globally, giving customers the optimal balance between lead-time and lifetime shots.

Key Benefits

- Micron-level accuracy: Vital for fx medical, fluid-handling parts and more.

- Multi-material options: Hard/soft over-moulding, liquid silicone, metal inserts.

- Scalable economics: From pilot to millions with the same team.

- Regulated-industry compliance: ISO 13485, MDR and FDA support.

- Global footprint: Identical processes in Europe, Asia and USA.