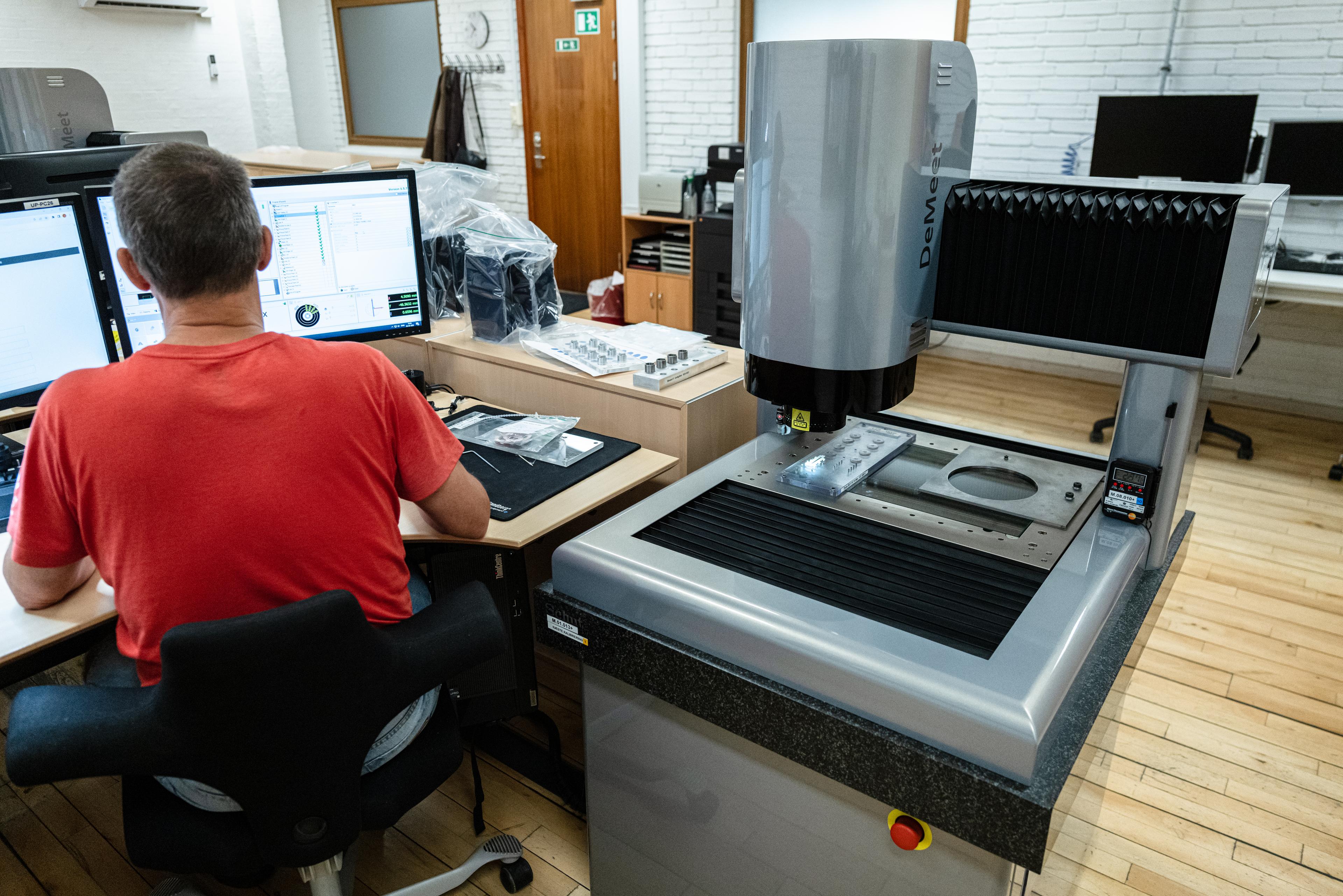

Design Support & Engineering

From concept to production-ready design – efficient and scalable

What this solution offers

All companies within SP Group are ready to help optimise both the design and manufacturability of your new component. In early-stage workshops, we evaluate which of our 10 manufacturing technologies best aligns with your targets for cost, volume, and product lifecycle.

If your product is being designed from the ground up, our specialist company Davinci 3D is here to support you – providing expert design input and advising on the most suitable production method from the very beginning.

Key Benefits

- Shorter time-to-market: Concept to pilot tooling in weeks

- Right-first-time manufacturing: DFM cuts tooling changes

- Lifecycle focus: Objective LCA comparisons of material options

- Cross-technology insight: Unbiased advice across ten processes

- Regulatory peace of mind: MDR, ISO 13485 and PPAP handled