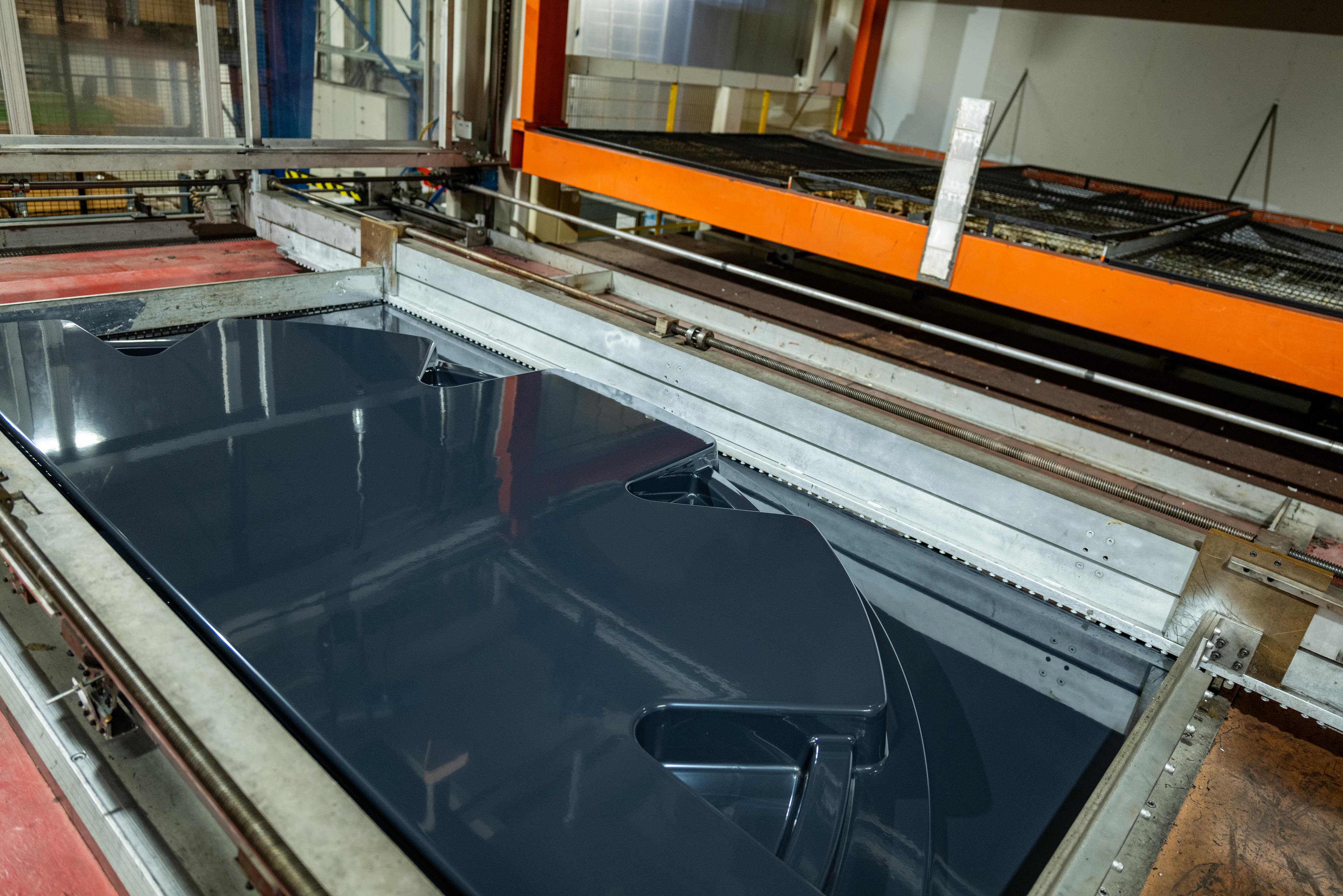

Thermoforming

Vacuum, twin-sheet and high-pressure forming up to 2.5 × 4.5 m

What this solution offers

SP Gibo operates some of Europe’s largest thermoforming presses, producing panels, machine guards and vehicle interior parts up to 4.5 × 2.5 m with depths of 700 mm.

Single-sheet vacuum forming suits prototypes and low volume; twin-sheet welding creates double-walled structures with integrated cavities; high-pressure forming yields sharp radii and fine textures rivaling injection parts at a fraction of tooling cost.

Five-axis CNC routers finish edges, and in-house painting, assembly and PUR over-foaming provide turnkey assemblies.

Key Benefits

- Very large parts: Replace metal or GRP panels economically.

- Low tool investment: Aluminium or wood tools ready in weeks.

- Twin-sheet strength: Lightweight yet stiff, with hidden channels.

- Rapid iterations: Design tweaks in days, not months.

- Recycled content: Use of secondary sheets supports ESG goals.