Extrusion

Tailor-made extrusion to your exact specification

What this solution offers

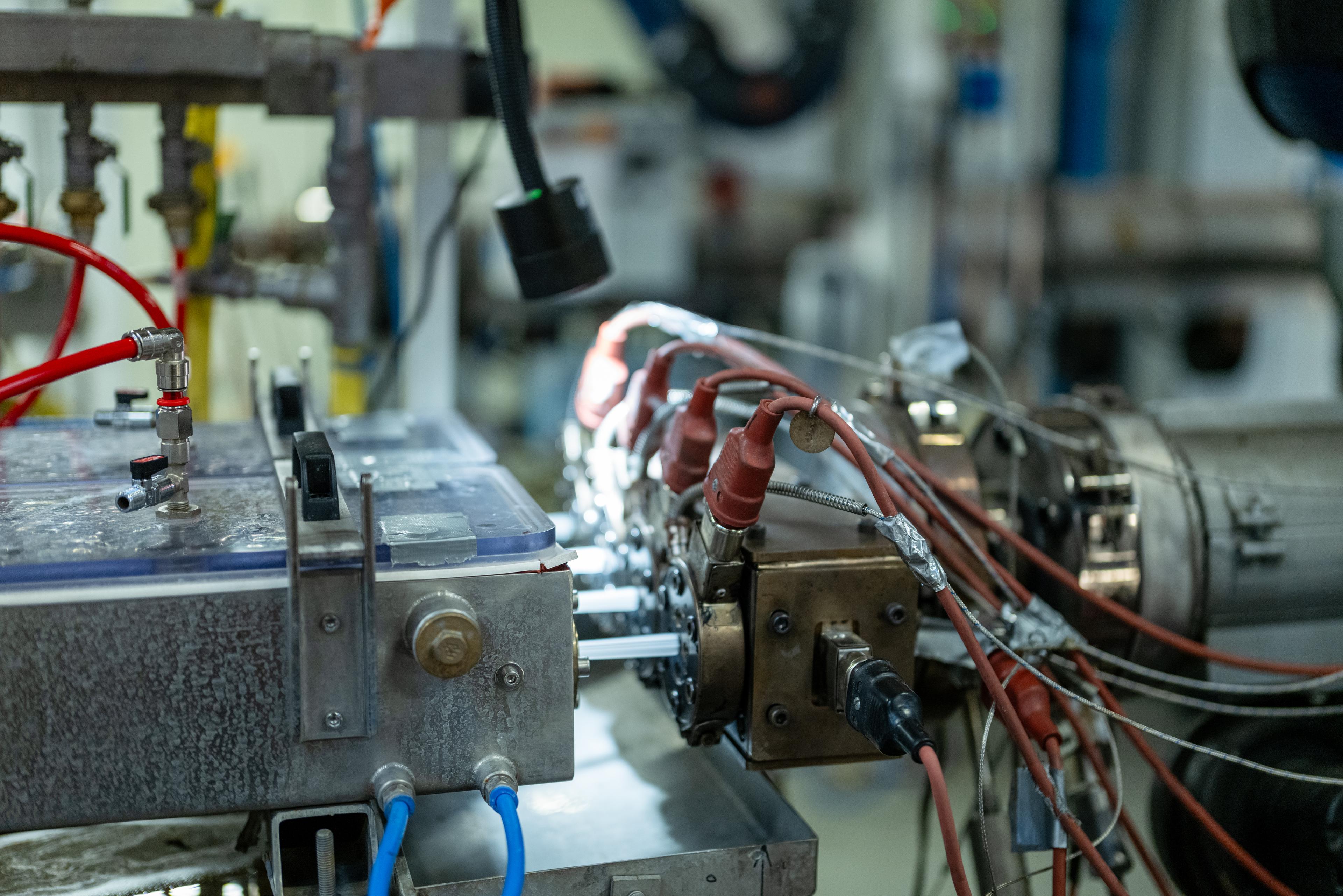

SP GIBO offers high-quality extrusion in a wide range of materials, producing tubes, hoses, and custom profiles. In-line punching, embossing, laser marking, and cut-to-length ensure components are ready for assembly upon delivery.

Extrusion also enables the production of multilayer products, allowing materials and colours to be combined – and making it easy to incorporate recycled plastics (regranulates) into your product design.

Key Benefits

- Design freedom in long lengths: Complex hollow chambers or gasket lips formed in one run

- Cost-effective tooling: Aluminium dies keep start-up budgets low

- Co-extrusion options: Combine rigid and soft zones for integrated seals

- Material flexibility: Available with high recycled content or bio-based compounds to meet environmental and regulatory goals

- End-to-end service: Engineering, die-making and finishing within one organisation