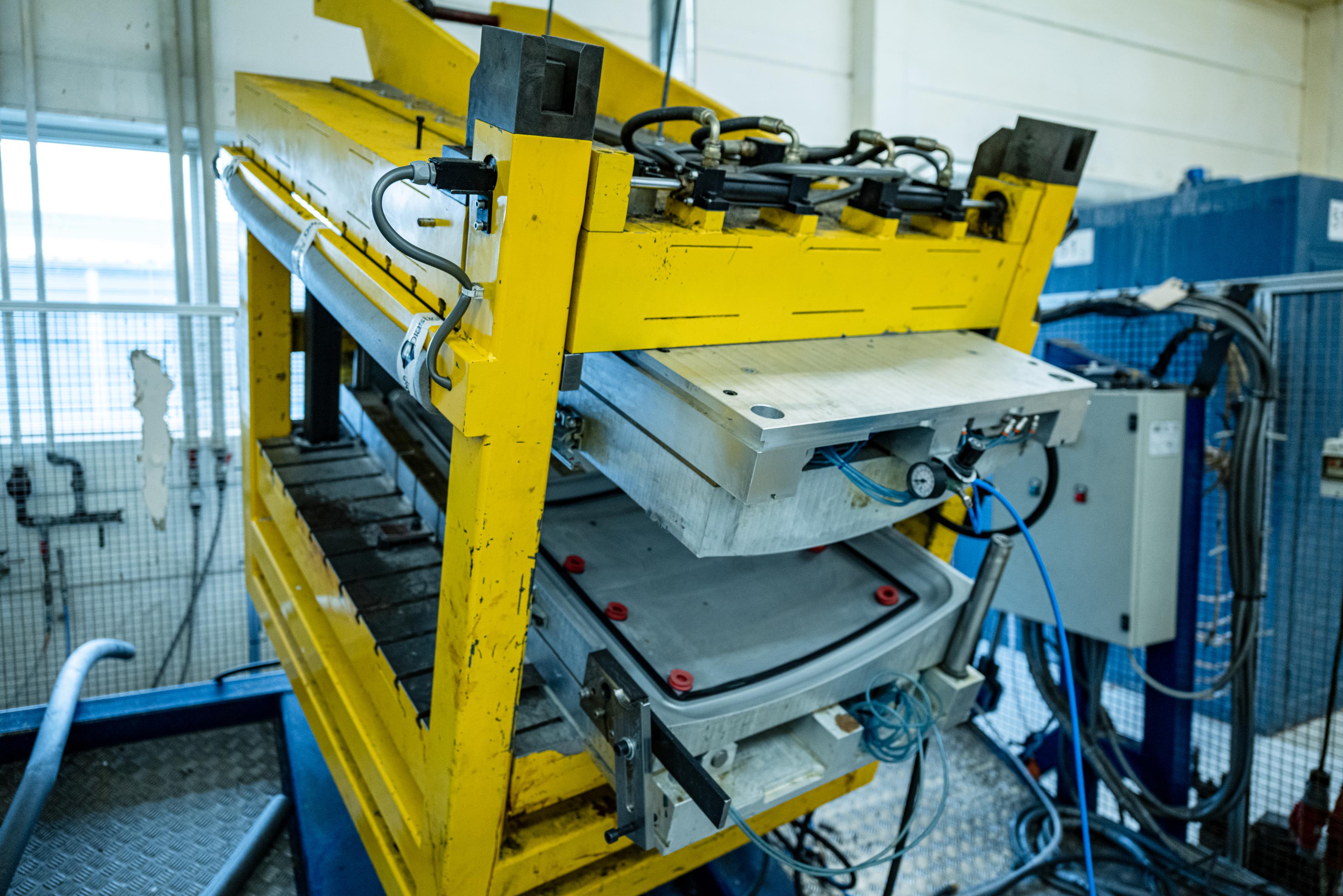

Reaction Injection Moulding - PUR

Crafting the Future with RIM-PUR: Combining Flexibility and Strength.

What this solution offers

Delving deep into the nuances of material science and advanced manufacturing, SP Group brings forth the expertise of Reaction Injection Moulding with PUR (Polyurethane). Harnessing the intrinsic properties of polyurethane, our RIM-PUR technique offers a blend of flexibility, durability, and impeccable finishes. When it's about crafting parts that need to be resilient yet lightweight, SP Group’s RIM-PUR process stands unmatched.

Key Benefits

- Flexibility and Rigidity: Polyurethane offers a unique blend of both, suitable for diverse applications.

- Superior Durability: Known for its wear and tear resistance, ensuring a longer product life.

- Efficient Thermal Insulation: Ideal for products requiring temperature regulation.

- Cost-Effective Production: Minimized waste and efficient moulding make the process economical.

- Versatile Design Potential: Allows for a wide range of shapes, sizes, and intricacies.