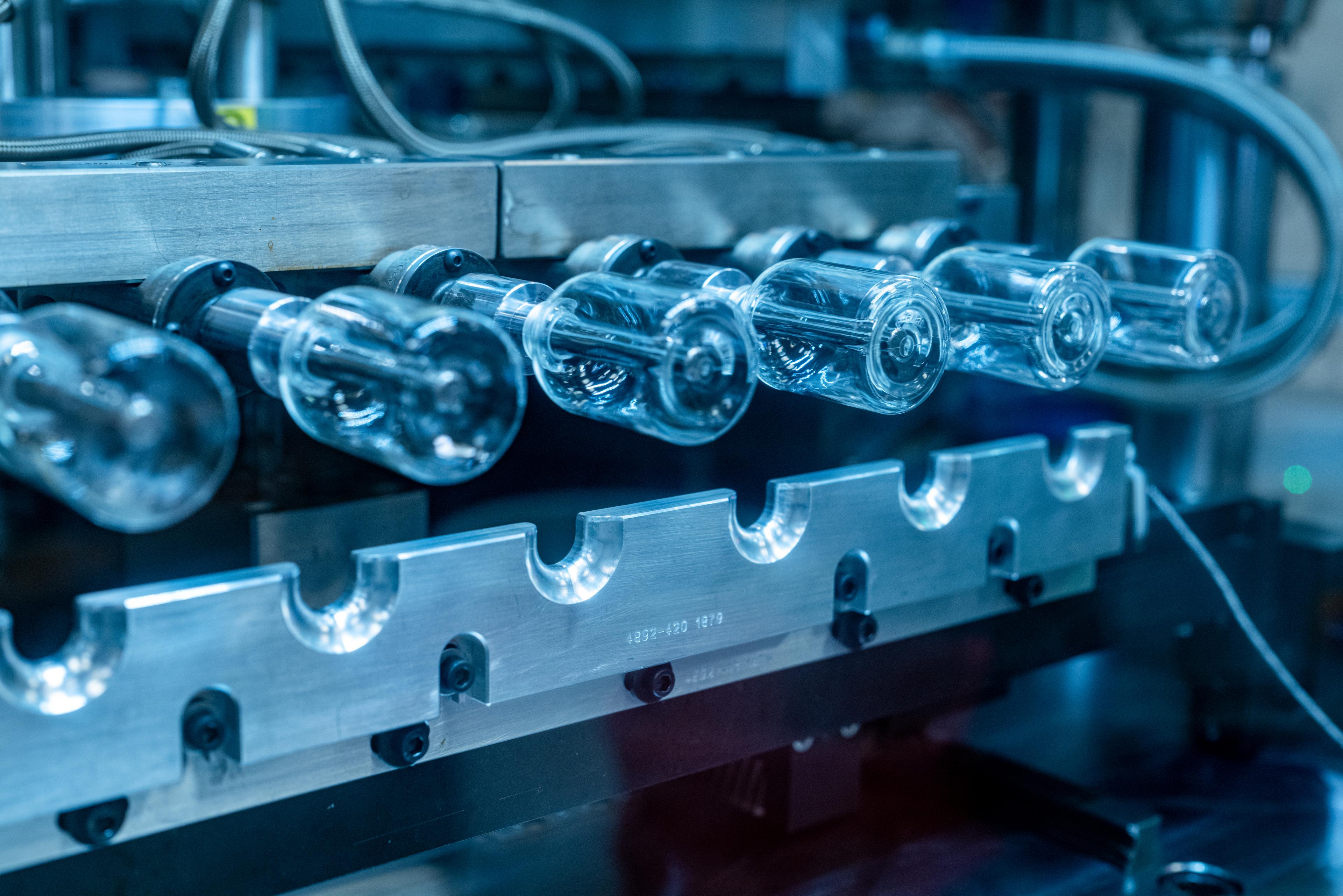

Injection Blow Moulding

Redefining Moulding Mastery with SP Group's Injection Blow Moulding Solutions.

What this solution offers

SP Group's relentless pursuit of excellence finds another strong ally in our Injection Blow Moulding services. This unique fusion of injection and blow moulding processes bridges the gap between design intricacy and production scalability. Today's market, saturated with consumer demands for bespoke solutions, leans on techniques like these to cater to nuanced requirements. From high-precision medical containers to flawless cosmetic packaging, our injection blow moulding technique has been setting industry benchmarks, carving a niche in delivering both function and form with impeccable finesse.

Key Benefits

- Unified Precision: Combines the accuracy of injection moulding with the versatility of blow moulding.

- High Integrity: Ensures seamless, airtight, and defect-free containers.

- Material Versatility: Capable of moulding diverse polymers to specific application needs.

- Efficiency: Streamlined process reduces production timelines and material wastage.

- Design Freedom: Allows for the creation of intricate shapes and unique product designs.