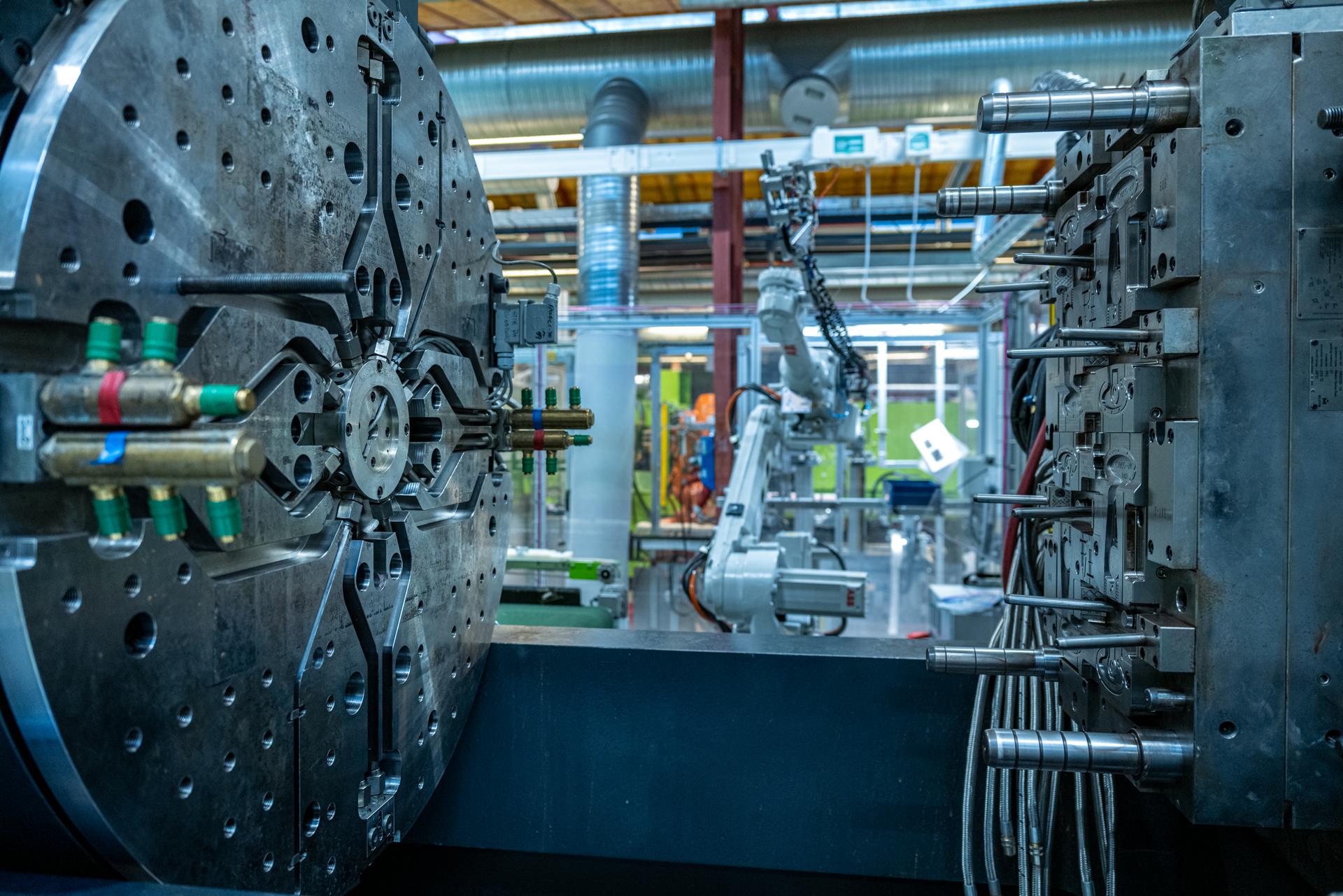

Machining of plastics

Short lead times and large flexibility

What this solution offers

Machining of plastic components is made by processing plastic components such as poles, blocks or plates. The process does not require any moulds and is thus suited for very small batch sizes.

SP Group's Machining services offers many possibilities and can often provide the right solution for components in low or medium volume.

Our services range traditional milling and turning operations to bending, welding and laser cutting.

Key Benefits

- Milling & Turning: components in small batches, delivered from day-to-day

- Laser Cutting: Transparent sheets cut into shape, leaving clean edges, with polished, smooth finish.

- Bending: Great alternative to gluing for simple parts, with a minimum of cost for production.

- Welding: the process is often used to create large special designed parts in small production series or large prototypes before serial production.